Single acting NBR rod seal incorporating a Polyester anti-extrusion header & POM anti-extrusion rings.

- Design -

Claron Style PDS rod seal is a 3 piece assembly consisting of a Nitrile Rubber sealing element which is backed up by a tough Thermoplastic elastomer header complete with an Acetal anti-extrusion ring on the I.D. The complete assembly forms a highly robust sealing unit for use in high pressure applications where shock loads and pressure spikes are present.

This seal is widely used in the mobile plant industry and is also a modern replacement for common veepac seals.

- Operating Conditions -

Maximum PressureMax Speed

| Temp. Range

|

m/s

| -30°C to 100°C

|

0,5

| 325 Bar

|

0,15

| 600 Bar

|

These range perameters are Maximum simultaneous conditions.

Optimum service conditions are affected by temperature, speed, pressure, surface finish and extrusion gaps.

- Housing -

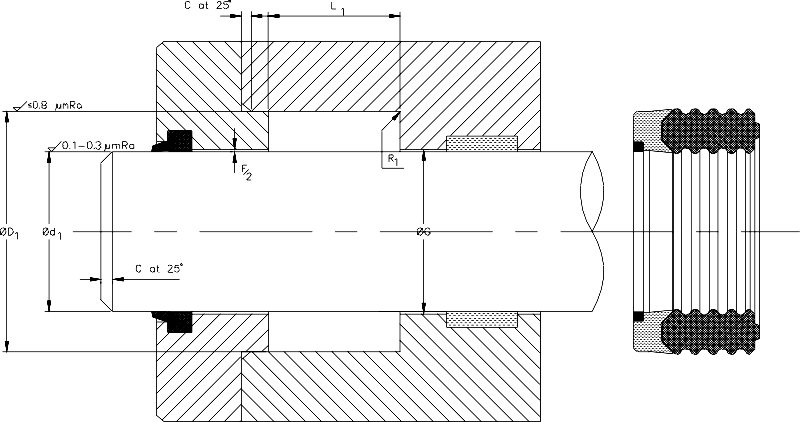

For surface finish and recommended lead in chamfers refer the illustration below. For housing dimensions and machining tolerances refer to the table of recommended sizes and

Tolerance Tables for value of tolerence symbols

- Fitting -

Style PDS is designed to be fitted into a split gland as shown in the illustration below. The seal can be supplied split to ease fitting if required. For the seal to function correctly, it is important that care be taken in fitting the seal within its housing. For details refer to

Seal Installation.